Flexible Foam Converting Capabilities

Hi-Tech Foam’s advanced manufacturing facility boasts a range of flexible foam converting capabilities. As a result, HTF provides foam products with PSA lamination, contour cutting, waterjet prototypes and more.

Skiving

Horizontal cutting of closed cell foams in sheets and rolls.

- 1.5mm to 100mm thick

- Roll lengths from 50 LF to 1,000 LF

Contour Cutting

Hi-Tech Foam’s contour cutting equipment can produce complicated curves and oblique angles.

Laminating

Bonding pressure sensitive adhesive to foam rolls and sheets.

- Acrylic and rubber based adhesive tapes in stock certified to OEM specifications

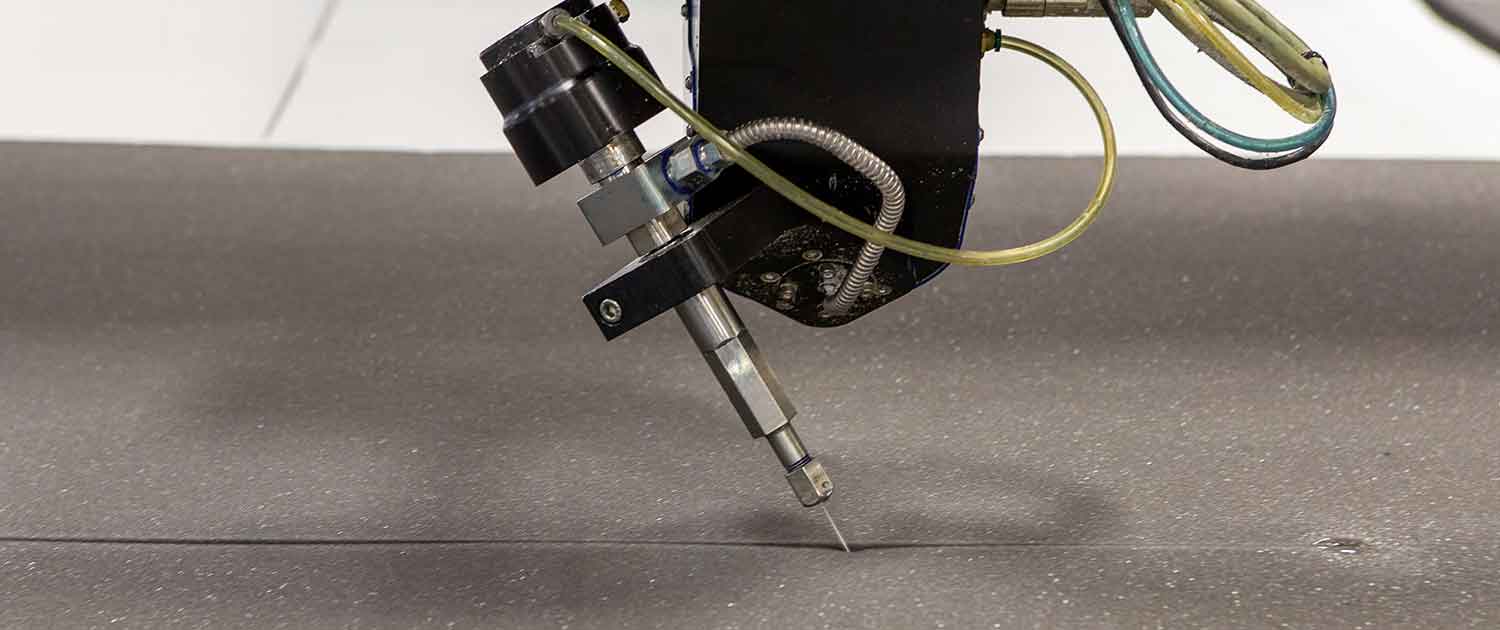

Waterjet Cutting

Hi-Tech Foam water jet cuts up to 6.0″ thick of high density foams. The multiple head 5-axis cutting mechanisms allow for cutting of complex, 3-dimensional shapes such as cones and various polygons. Waterjet cutting eliminates edge concavity found with die cutting thick foams.

Heat Welding

Bonding foam sheets to build custom thickness and composites of different densities.

Slitting

Vertically cutting rolls of foam and adhesive to narrow widths.

- 1.0″ wide to 60″ wide rolls